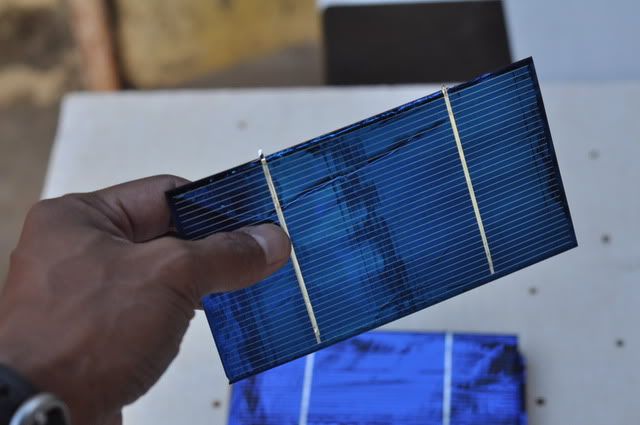

Solar Cell A solar cell (also called photovoltaic cell or photoelectric cell) is a solid state electrical device that converts the energy of light directly into electricity by the photovoltaic effect.

Solar Panel

A solar panel (photovoltaic module or photovoltaic panel) is a packaged interconnected assembly of solar cells, also known as photovoltaic cells. The solar panel can be used as a component of a larger photovoltaic system to generate and supply electricity in commercial and residential applications.

Negative and Positive..

The front side (blue side / sunny side) is the negative side of a cell. The two thick white lines are the bus bars they are the negative terminals of the cell. The back side with 6 square dots is the positive side.

Tabbing Wire, Bus Wire, Flux pen and Soldering Iron

These are the basic materials that you need in making you own Solar Panel.. and of course the solar cells.

Tabbing wire.. this is what you will use in connecting all your solar cells to make a panel.

Bus wire.. thicker than the tabbing wire, use to connect your solar cells array together to complete your solar panel.

Flux Pen.. is designed for easier soldering of tab wire to electroplax or many other soldering purposes.

Soldering Iron..

Tabbing/Soldering of Solar Cells...

At first, tabbing or soldering cell maybe the hardest and frustrating part in solar panel making. But with a little practice and the help of Flux pen and a

decent Soldering Iron it'll be a lot easier.

The pictures below will show you how to solder a tabbing wire. In this example I used a short tabbed 3x6 polycrystalline cell.

1.) Cut around 3 inches of tabbing wire.

Since in this example is a 3x6 short tabbed cell,

you will cut around 3 inches of tabbing wire.

If in case you are going to use 3x6 untabbed cells, you will be needing twice the length of tabbing

wire.

2.) Apply flux to short tabbing wire..

Photos below show that I'm applying flux on the positive side but you can also do it on the other side. Your choice..

3.) Solder the 3-inch tabbing wire..

This is how it will look like after you're done soldering. =====>>

There are times that the tabs are too short and it's hard to solder it on the other side..

Now you have yourself a full tabbed cell..

The number depends on how much voltage of panel you are going to make.